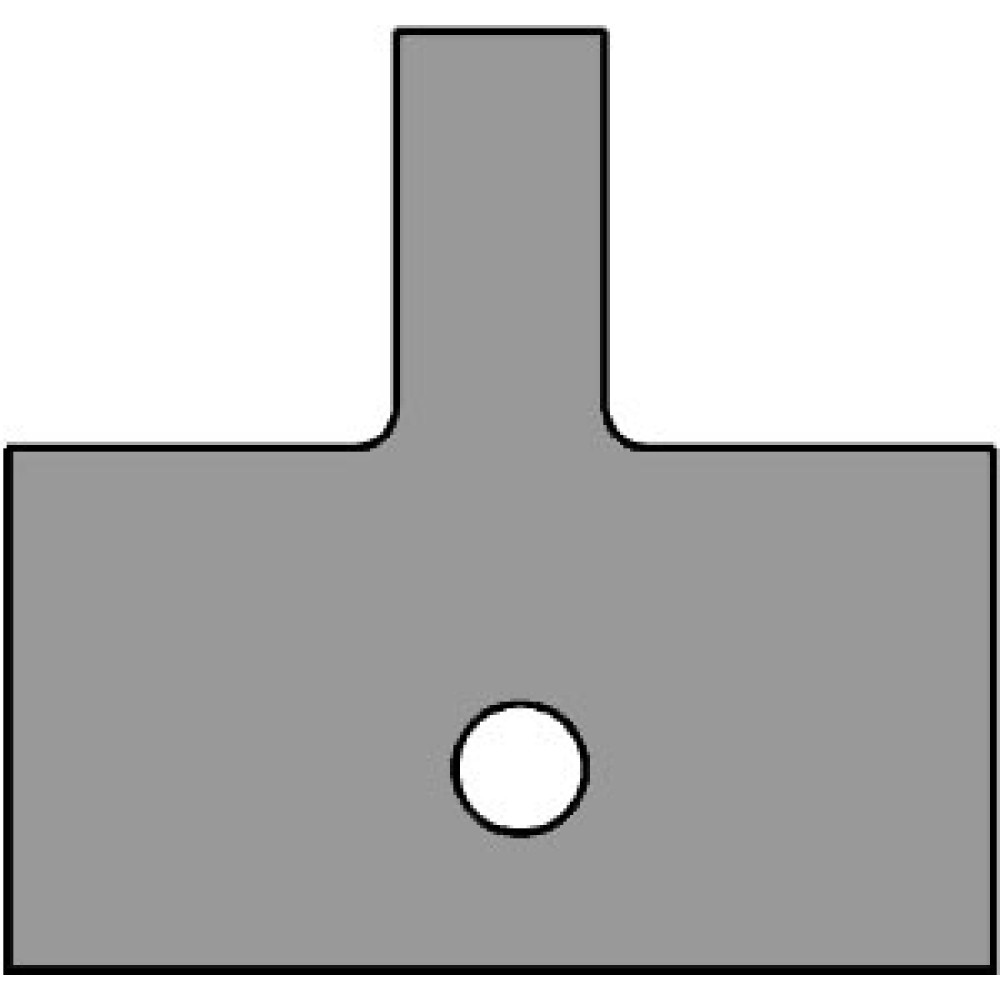

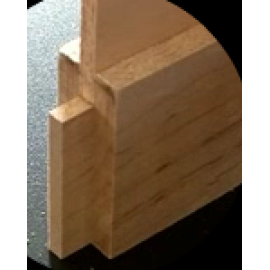

Byrd Stile Shaper Cutter loaded with #5SE Shaker Pattern Inserts Eased Edge Choice of Bore

Product Description

Easily Change tips at your shop to start “like new”. Either replace the tips with the identical pattern, or buy a set of tips with a different pattern. Be sure to check with us to see if the shapes are compatible. Usually the same general pattern and same hand tip will go in the same head.

- Major Diameter 4" for 3/4" or 4-1/2" for 1-1//4"

- Please specify bore when ordering, add a note in checkout field.

- Cutting Edge Length 30mm for stock 3/4” to 7/8”

- Comes loaded with 5 SE "eased edge" (allows you to paint and stain under the stile on an assembled door so when panels move which they will you do not see the unsighty lines where finish or paint was not applied.05" r) inserts can also run 5 LS, 5 RS, 5S Carbide inserts**

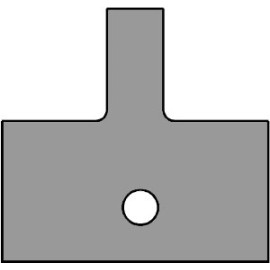

- Tobgue and groove Centered in cutter "center cut"

-

- Wrench included

- Bore 3/4 "

- Balanced & Verified

- Made in USA

- Black Oxide Finish

- Useful in other woodworking applications.

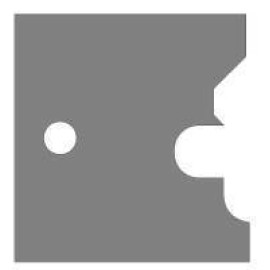

**One pattern of the Shaker cutters has a symmetrical pattern, while in the other we have both right hand and left hand rotation patterns in stock. The tips we make are identical for the two bore sizes. The typical groove dimension is ½” long by 1/4” wide. We designate the left hand tools CCW rotation, material face down. The right hand tools would be CCW rotation, material face up. The tip dimension itself is 30mm wide which will easily accommodate a 3/4” to 7/8” stock width. Any of the same hand stile or rail tips will fit in any of the corresponding heads. The exceptions would be the glass door patterns with non-glass door and the Shaker patterns. The 3/4” bore tools all have a 4” large OD and a 3” small OD. You can use a 3” bearing rub collar for arched doors. The collars are kept in stock with this diameters, but we can manufacture whatever diameter you need. The difference in the “stain relief” pattern heads is there is a small radius ground on the tips in the corners. They are also known as “eased edge” tips. Note that typically Shaker bodies are required for the corresponding tips, this is because backing is required for the tip to not break in operation.

-270x270.jpg )

-270x270.jpg )